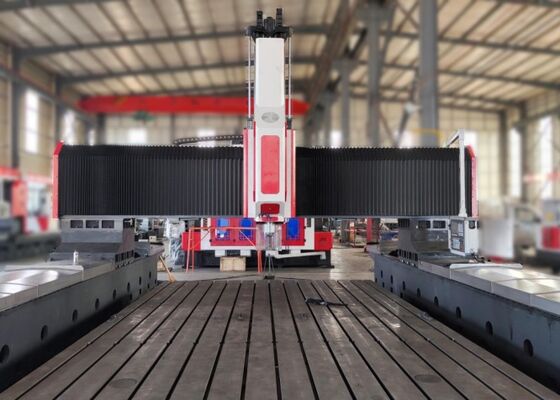

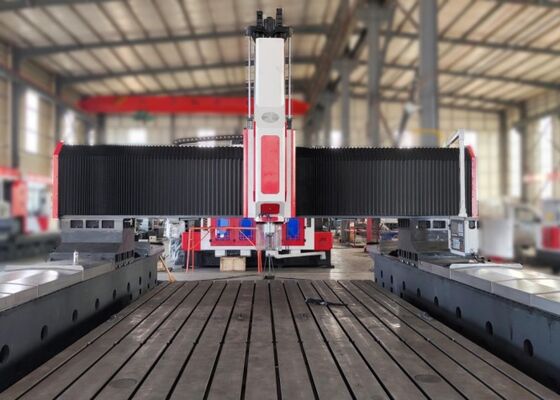

শিল্প সিএনসি প্লেট ড্রিলিং মেশিন 6000x6000 মিমি ওয়ার্কপিস ক্যাপাসিটি 22 কিলোওয়াট সার্ভো স্পিন্ডল মোটর সহ

প্রয়োগ:

এই সিএনসি গ্যান্ট্রি ফ্ল্যাঞ্জ ড্রিলিং এবং ফ্রিলিং মেশিনটি বিশেষভাবে প্লেট ওয়ার্কপিস এবং কাঠামোগত উপাদানগুলিতে ড্রিলিং, চ্যামফারিং, ট্যাপিং, ফ্রিলিং এবং বোরিং অপারেশন পরিচালনা করার জন্য ডিজাইন করা হয়েছে।এটি ফ্ল্যাঞ্জের মতো ওয়ার্কপিসের জন্য উচ্চ দক্ষতার গর্ত ড্রিলিং পারফরম্যান্স সরবরাহ করে, ডিস্ক, রিং এবং প্লেট যার বেধ নির্ধারিত কার্যকর পরিসীমা মধ্যে পড়ে। উভয় গর্ত এবং অন্ধ গর্ত মাধ্যমে প্রক্রিয়া করার ক্ষমতা সঙ্গে,সরঞ্জামগুলি একক উপাদান উপাদান এবং যৌগিক উপকরণগুলির সাথে শক্তিশালী সামঞ্জস্যতা প্রদর্শন করেউন্নত ডিজিটাল কন্ট্রোল প্রযুক্তি দিয়ে সজ্জিত, মেশিন টুল উচ্চতর অপারেশন সুবিধা নিশ্চিত করে। এটি উচ্চ নির্ভুলতা স্বয়ংক্রিয় উত্পাদন সক্ষম,বিভিন্ন প্রকারের প্রক্রিয়াকরণের চাহিদা পূরণ করে, এবং বড় আকারের উত্পাদন কর্মপ্রবাহ সমর্থন করে।

স্পেসিফিকেশনঃ

| ওয়ার্কপিসের আকার |

LxW |

৬০০০x৬০০০ মিমি |

| গ্যান্ট্রি উচ্চতা |

৮০০ মিমি

(এটি ফাউন্ডেশনের উপর নির্ভর করেও নির্ধারণ করা যেতে পারে)

|

| ওয়ার্কবেঞ্চ |

টি-স্লটের প্রস্থ |

২৮ মিমি |

| ড্রিলিং পাওয়ার হেড |

কুইটি। |

2 |

| স্পিন্ডল কোপ |

বিটিআই |

|

সর্বাধিক ড্রিলিং ব্যাসার্ধ

(সাধারণ কার্বন ইস্পাত)

|

Φ80 মিমি |

| সর্বোচ্চ.ঘনতা |

≤১৫০ মিমি |

| ট্যাপিং ব্যাসার্ধ |

M3-M36 |

| স্পিন্ডল গতি |

30~3000 r/min |

| সার্ভো স্পিন্ডেল মোটর পাওয়ার |

২২ কিলোওয়াট |

| স্পিন্ডলের নীচের প্রান্ত থেকে কাজের টেবিলের দূরত্ব |

২০০-৮০০ মিমি |

|

পাওয়ার হেডের পাশের গতি(এক্স অক্ষ)

|

সর্বাধিক অনুভূমিক স্ট্রোক |

৬০০০ মিমি |

| পার্শ্বীয় গতির গতি |

0 ~ 8 r/min |

| পার্শ্বীয় গতির জন্য সার্ভো মোটর শক্তি |

২x৪.২ কিলোওয়াট |

|

গ্যান্ট্রি লম্বা গতি (Y অক্ষ)

|

সর্বাধিক ফিড স্ট্রোক |

৬০০০ মিমি |

| ফিড চলমান গতি |

০-৮ মিটার/মিনিট |

| ফিড সার্ভো মোটর শক্তি |

২x৪.২ কিলোওয়াট |

| উল্লম্ব র্যাম ফিড মোশন (Z অক্ষ) |

সর্বাধিক স্ট্রোক |

৬০০ মিমি |

| চলমান গতি |

০-৬ মিটার/মিনিট |

| সার্ভো মোটর শক্তি |

2x3.6kW (ব্রেক) |

| তিন অক্ষের অবস্থান সঠিকতা |

X/Y/Z/A/B/C |

±0.01/1000 মিমি |

| তিন-অক্ষ পুনরাবৃত্তি অবস্থান সঠিকতা |

X/Y/Z/A/B/C |

±0.01/1000 মিমি |

| সামগ্রিক আকার |

LxWxH |

11000x9500x4000 মিমি |

সরঞ্জাম কাঠামোঃ

এই সিএনসি গ্যারেন্ট্রি ড্রিলিং এবং চিহ্নিতকরণ মেশিনটি বিশেষভাবে কাস্ট আয়রন বিছানা ওয়ার্কবেঞ্চ, একটি চলনযোগ্য গ্যারেন্ট্রি সমাবেশ, একটি ক্রসিং স্যাডল, একটি ড্রিলিং-ফ্রিলিং পাওয়ার হেড,স্বয়ংক্রিয় তৈলাক্তকরণ এবং সুরক্ষা ব্যবস্থা, একটি সার্কুলেটিং কুলিং মডিউল, একটি সংখ্যাসূচক নিয়ন্ত্রণ (এনসি) সিস্টেম, এবং একটি বৈদ্যুতিক নিয়ন্ত্রণ ইউনিট। রোলিং গাইডগুলি শক্তিশালী লোড বহন স্থিতিশীলতা এবং সঠিক গতি অবস্থান প্রদান করে,যখন উচ্চ নির্ভুলতা বল স্ক্রু ট্রান্সমিশন প্রক্রিয়া ব্যতিক্রমী অবস্থান সঠিকতা এবং অসামান্য অপারেশন পুনরাবৃত্তি নিশ্চিত.

পণ্যের বৈশিষ্ট্য

1ড্রিলিং পাওয়ার হেডঃ

ড্রিলিং পাওয়ার হেড একটি বিশেষ সার্ভো স্পিন্ডল মোটর দিয়ে সজ্জিত করা হয়,যা স্পিড কমানোর জন্য একটি দাঁতযুক্ত সিঙ্ক্রোনস বেল্ট ব্যবহার করে এবং একটি বিশেষ সুনির্দিষ্ট স্পিন্ডল চালানোর জন্য টর্ক বৃদ্ধি করে. স্পিন্ডল একটি ছয় সারি জাপানি কৌণিক যোগাযোগ ভারবহন বিন্যাস গ্রহণ করে (সামনে চার, পিছনে দুই) ধাপবিহীন গতি নিয়ন্ত্রণ উপলব্ধি করতে। একটি বায়ুসংক্রান্ত টুল পরিবর্তন সিস্টেম দিয়ে সজ্জিত,স্পিন্ডল দ্রুত এবং সুবিধাজনক সরঞ্জাম প্রতিস্থাপন সক্ষমফিড মোশন একটি বল স্ক্রু সঙ্গে জোড়া একটি servo মোটর দ্বারা চালিত হয়।এক্স এবং ওয়াই অক্ষ লিঙ্কিং কার্যকারিতা সমর্থন করে এবং রৈখিক এবং বৃত্তাকার অন্তর্ভুক্তির ক্ষমতা অর্জনের জন্য অর্ধ-বন্ধ লুপ নিয়ন্ত্রণ ব্যবহার করে. স্পিন্ডল শেষটি একটি BT50 কোপার গর্তের বৈশিষ্ট্যযুক্ত এবং একটি উচ্চ গতির ঘূর্ণন জয়েন্টের সাথে সংহত করা হয়েছে, যা স্পিন্ডলের মাধ্যমে শীতল তরল সরবরাহের সাথে উচ্চ গতির ইউ-ড্রিল মেশিনিংয়ের সুবিধার্থে।

2ট্রান্সমিশন সিস্টেম:

তাইওয়ান থেকে আসা গাইড রেল এবং একটি উচ্চ-নির্ভুল স্লাইডার ডিজাইনের বৈশিষ্ট্যযুক্ত, সিস্টেমটি মসৃণ অপারেশনাল পারফরম্যান্স এবং উন্নত ভারী লোড বহন ক্ষমতা নিশ্চিত করে।

এক্স-অক্ষ দুটি রোলিং লিনিয়ার গাইড রেলকে পার্শ্বীয় গাইডিং এবং লোড বহনকারী ট্র্যাক হিসাবে গ্রহণ করে, উচ্চ গতির ড্রিলিং অপারেশনগুলির প্রয়োজনীয়তা পুরোপুরি পূরণ করে। এক্স-অক্ষ ট্রান্সমিশনের জন্য,একটি এসি সার্ভো মোটর একটি যথার্থ বল স্ক্রু চালায় রৈখিক গতি উপলব্ধি করতে.

Y-অক্ষ দুটি ভারী দায়িত্ব রোলিং রৈখিক গাইড রেল দিয়ে সজ্জিত, প্রতিটি গাইড রেল উপর মাউন্ট করা তিনটি বর্গাকার রেলগাড়ি সঙ্গে সমষ্টিগতভাবে Y-অক্ষ স্লাইডিং প্রক্রিয়া গঠন।এই কাঠামোগত নকশাটি কেবল গ্যান্ট্রি ফ্রেমের উচ্চ অনমনীয়তা এবং শক্তির চাহিদা পূরণ করে না, তবে একটি কম ঘর্ষণ সহকারি সহ প্রযুক্তিগত সুবিধা প্রদান করে, উচ্চ গতির গতি, উচ্চতর কম্পন damping কর্মক্ষমতা, এবং বর্ধিত সেবা জীবন। Y- অক্ষ ড্রাইভ দ্বৈত servo মোটর সিঙ্ক্রোন ড্রাইভ প্রযুক্তি ব্যবহার করেঃএকটি সার্ভো মোটর প্রতিটি পাশের উপর synchronously বল স্ক্রু ঘূর্ণন চালানোর জন্য কনফিগার করা হয়, যার ফলে গ্যান্ট্রি ফ্রেমের চলাচল এবং সুনির্দিষ্ট সিএনসি মেশিনিং অর্জন করা সম্ভব হয়।

.

.

এই উচ্চ-পারফরম্যান্স সিএনসি গ্যান্ট্রি শিল্প মেশিনটি বিশেষভাবে প্লেট এবং শীট ধাতব উপাদানগুলির উপর ড্রিলিং এবং চিহ্নিতকরণ অ্যাপ্লিকেশনগুলির জন্য ডিজাইন করা হয়েছে।প্লেট টাইপ ওয়ার্কপিস এবং কাঠামোগত অংশের যথার্থ মেশিনিং নিশ্চিত করার জন্য সুদর্শনভাবে ডিজাইন করা, এটি প্রসেসিং ফ্ল্যাঞ্জ, ডিস্ক, রিং, ফ্ল্যাট প্লেট এবং অনুরূপ উপাদানগুলির জন্য ডেডিকেটেড সামঞ্জস্যতা সরবরাহ করে।একটি মৌলিক প্রয়োজনীয়তা হল যে workpiece বেধ কঠোরভাবে মেশিনের পূর্বনির্ধারিত কার্যকর যন্ত্রপাতি পরামিতি মেনে চলতে হবে.

এই সরঞ্জামগুলি স্টিলের কাঠামো তৈরির ইনস্টলেশনের মধ্যে কাঠামোগত প্লেট এবং সংযোগকারী উপাদানগুলির উপর নির্ভুলতা ড্রিলিং এবং ফ্রিলিং অপারেশন সম্পাদন করে,ইস্পাত কাঠামোর স্থিতিশীল সমাবেশের জন্য একটি শক্তিশালী ভিত্তি স্থাপনবায়ু শক্তি ক্ষেত্রে,এটি বায়ু টারবাইন টাওয়ার এবং ফ্ল্যাঞ্জের জন্য উচ্চ-নির্ভুলতা মেশিনিং সমাধান সরবরাহ করে উদাহরণস্বরূপ, তীব্র বাতাস, তাপমাত্রা পরিবর্তনের জন্য) । সেতু নির্মাণ প্রকল্পের জন্য, সরঞ্জামগুলি সেতুর গ্রিড এবং সমর্থন ব্র্যাকেটগুলি প্রক্রিয়া করে, স্থিতিশীল গঠন সহজতর করে,দীর্ঘস্থায়ী সংযোগগুলি যা সেতুর বর্ধিত পরিষেবা জীবন জুড়ে গতিশীল বোঝা সহ্য করতে ডিজাইন করা হয়েছে.

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!